- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

How Can Flat Wire Alpha Coil Winding Machines Improve Production Accuracy and Throughput?

2025-12-12

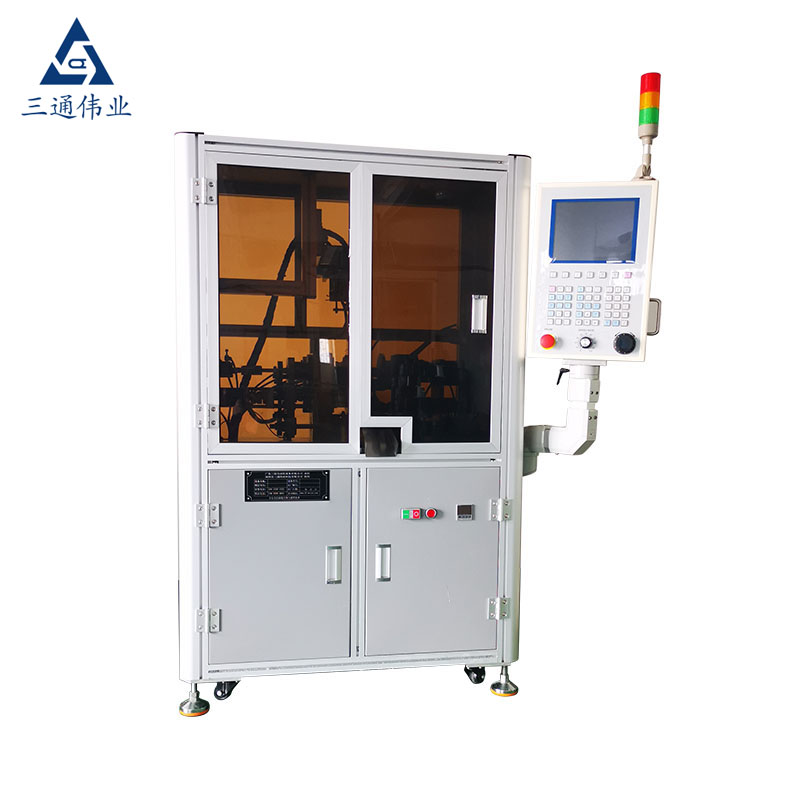

The Flat Wire Alpha Coil Winding Machine is engineered for high-precision winding of flat conductors used in EV motors, transformers, inductors, and advanced electronic assemblies. This equipment is designed to solve the industry-wide challenge of maintaining strict dimensional tolerances while achieving stable, repeatable output at scale.

Key Technical Parameters

| Parameter | Specification |

|---|---|

| Applicable Wire Type | Copper/Aluminum Flat Wire |

| Flat Wire Width Range | 2–20 mm (customizable) |

| Flat Wire Thickness Range | 0.5–5 mm (customizable) |

| Maximum Winding Speed | 800–1200 RPM depending on coil type |

| Spindle Drive | Servo-controlled, high-torque motor |

| Tension Control System | Closed-loop automatic tension monitoring |

| Layering Accuracy | ±0.02 mm |

| Coil Compatibility | EV traction motors, inductors, transformers, customized stators |

| Control System | Multi-axis CNC system with precision servo drives |

| Output Mode | Automatic or semi-automatic configuration |

| Safety System | Overload detection, auto-stop, emergency brake |

| Power Requirement | 380V/50–60Hz |

| Machine Footprint | Designed for compact industrial integration |

How Does the Flat Wire Alpha Coil Winding Process Achieve High Dimensional Consistency?

Flat wire introduces challenges not present in round wire winding: edge alignment, uniform layering, temperature stability, and tension precision. The Flat Wire Alpha Coil Winding Machine addresses these constraints through a coordinated motion-control architecture that synchronizes spindle rotation, wire feeding, tension compensation, and layering trajectory planning.

The machine’s servo-driven spindle ensures that even at higher RPMs, coil geometry remains consistent across each layer. Stability is further enhanced by a closed-loop tension system that continuously adjusts for wire unspooling resistance, temperature-related elasticity, and micro-variations in wire thickness. These controls maintain constant tension, preventing deformation and edge collapse—two major defects in flat wire winding.

Equally important is the CNC-based layering mechanism. The multi-axis controller calculates the placement of each wire pass based on pre-programmed design parameters. It adjusts the wire’s lateral position in real time, compensating for micro-drift and ensuring even distribution. With tolerances as tight as ±0.02 mm, the resulting coil meets stringent requirements for inductance uniformity, thermal efficiency, and electromagnetic performance.

Manufacturers increasingly face demands for high-density coils, particularly in electric mobility and renewable energy sectors. Flat wire maximizes slot fill factor, and this machine’s precision engineering allows technicians to exploit that advantage without compromising mechanical strength. By maintaining symmetry across layers, the machine ensures predictable electrical characteristics—critical in applications where heat dissipation and magnetic field stability determine overall system efficiency.

As industries adopt more compact motor designs, tight dimensional control becomes non-negotiable. The Flat Wire Alpha Coil Winding Machine supports this transition by offering an automated path to consistent geometry, reduced scrap rate, and minimized human dependency. This makes it a strategic investment for facilities that prioritize throughput, repeatability, and quality stability in their production flows.

How Does Automation in Flat Wire Alpha Coil Winding Machines Influence Production Efficiency and Workload Reduction?

Industrial production environments increasingly require equipment that reduces manual intervention while boosting throughput. The Flat Wire Alpha Coil Winding Machine integrates automation at critical stages—wire feeding, winding, tension control, and coil shaping—to shorten processing cycles and remove operator-dependent inconsistencies.

Automated wire guidance ensures that wire from the payoff unit is straightened, oriented, and fed at a constant angle. This eliminates common manual issues such as wire twisting, micro-scratches, and uneven positioning. Additionally, the automated layer-by-layer motion reduces setup and calibration time. Once parameters are entered, the system replicates the program flawlessly across all future cycles.

The machine’s CNC controller allows for batch production with preset recipes. Manufacturers can store multiple coil specifications and switch between them without lengthy recalibration. This makes production scheduling more flexible and supports just-in-time workflows.

Automation also helps reduce labor fatigue and ergonomic risks. Flat wire is harder to manipulate manually due to its rigidity and edge geometry. With automation handling tension and positioning, operators focus primarily on supervisory tasks rather than repetitive physical work.

Data monitoring enhances this automation ecosystem. Real-time metrics—such as tension trends, spindle torque, coil progress, and layering conformity—are displayed on the HMI. Deviations trigger auto-corrections or machine stops to prevent further defects.

This integration of automated controls reduces rework rates, accelerates cycle times, and maintains constant output quality. Large-scale factories benefit from predictable shift-to-shift performance, while smaller facilities achieve higher productivity without needing a large, highly specialized workforce.

How Will Advancements in Flat Wire Winding Technology Shape Future Manufacturing Demands?

Transformations in the automotive, power electronics, and industrial automation sectors are reshaping expectations for coil manufacturing equipment. As electrification expands globally, flat wire coil designs are becoming a dominant solution due to their thermal efficiency and compact winding characteristics.

Future developments in flat wire winding machinery are expected to focus on:

-

Increased integration of AI-driven process optimization

Machine learning algorithms embedded into CNC controllers will likely analyze production data and automatically adjust winding trajectories, tension responses, and RPM patterns. The goal is to achieve real-time optimization of defect reduction and energy efficiency. -

Higher slot fill ratios

Equipment will support more complex layering geometries, pushing slot fill capabilities closer to theoretical maximums. Improved shaping tooling and advanced servo actuators will make this possible without compromising insulation integrity. -

Material-adaptive controls

Future systems may identify wire properties automatically—such as hardness, elasticity, or surface friction—and modify winding parameters accordingly. This will be valuable for specialty alloys and emerging conductive composites. -

Integration with Industry 4.0 platforms

Machines will increasingly support remote diagnostics, predictive maintenance, and cloud-based quality tracking. Manufacturers will leverage data analytics to prevent downtime and plan coil production with higher accuracy. -

Eco-oriented manufacturing priorities

With sustainability becoming central to industrial strategy, coil winding machinery is expected to adopt designs that minimize energy consumption, reduce scrap, and optimize heat management.

As the landscape evolves, businesses that adopt such advanced equipment early gain an operational advantage by producing more compact, thermally stable, and electrically efficient coils. The Flat Wire Alpha Coil Winding Machine, already designed with precision controls and automation, aligns with these future trends and provides a foundation that can be upgraded or integrated into more advanced manufacturing ecosystems.

How Can Manufacturers Determine the Right Flat Wire Alpha Coil Winding Machine for Their Production Requirements?

Selecting appropriate winding equipment depends on a clear assessment of application demands, wire specifications, production volume, and coil complexity. The Flat Wire Alpha Coil Winding Machine offers a versatile range suited to various industrial requirements, but understanding its suitability requires evaluating several criteria.

First, the dimensional tolerance required in the final coil must match the machine’s layering accuracy. For EV traction motors, where symmetry directly impacts electromagnetic balance, the machine’s ±0.02 mm precision becomes a significant advantage. For inductors or transformer windings, consistent tension control ensures uniform inductance values and reduced core losses.

Second, coil complexity levels determine the necessity of multi-axis motion capability. Complex geometries require precise synchronization between wire feed, spindle speed, and lateral positioning. The CNC system in this machine supports multi-layer strategies, enabling programs that handle intricate winding paths.

Third, output requirements influence the need for automation. Facilities with high-volume demand benefit from automated setups, recipe storage, and continuous monitoring. Smaller facilities still gain from the machine’s precision but may configure it in a semi-automatic mode to reduce initial investment.

Fourth, maintenance and upgrade potential should be considered. Modular components, standardized servo drives, and accessible control systems ensure long-term serviceability. Manufacturers planning to scale up can integrate the machine with digital monitoring systems or expand with automated loading solutions.

When chosen correctly, the Flat Wire Alpha Coil Winding Machine becomes a long-term asset that combines precision engineering with scalable productivity, enabling manufacturers to improve coil performance while reducing operational downtime.

Frequently Asked Questions

1. How does the tension control system prevent deformation in flat wire coils?

The machine uses a closed-loop tension feedback mechanism that continuously measures actual tension and adjusts it using servo-driven compensation units. By reacting instantly to wire unspooling resistance, wire hardness variation, or acceleration forces, the system keeps tension within set parameters. This prevents edge folding, micro-cracks, and uneven layering—common issues in flat wire applications.

2. How can production changeover be performed efficiently for different coil models?

The controller allows operators to store multiple winding programs, each containing speed curves, tension parameters, trajectory data, and layer counts. During changeover, the operator selects the desired program, and the machine automatically configures its axes, feed system, and tension unit. This minimizes calibration time and reduces the risk of manual errors.

As the global demand for high-density, thermally efficient coils continues to rise, the Flat Wire Alpha Coil Winding Machine stands out as a robust solution for manufacturers aiming to enhance precision and productivity. Its advanced motion control, closed-loop tension system, and automated functions position it as a strategic tool for future-ready coil production.

For facilities seeking professional-grade performance and reliable engineering, equipment from Santong offers a strong combination of technical capability and long-term operational stability. To explore specifications, production strategies, or integration options, contact us for detailed consultation and support.